Best 3D Printed Cars

Last updated:

3D Printing has facilitated a large advance in the design, manufacture and performance of cars.

This is due to the layered construction method that 3D printing utilizes to build parts, and the ability to accurately place building materials anywhere within each of those layers.

It creates the following advantages:

Rapid design revisions

Depending on the complexity of the shape, 3D printing is generally faster than most traditional manufacturing methods like machining, molding and casting.

So when it comes to the large amount of prototyping that takes place during the design process in the automotive industry, the use of 3D printing greatly helps reduce the amount of time it takes to finalise car designs and start production. With few setup procedures, new or adjusted car parts can start printing as soon as the design has been completed.

Additionally, multiple parts or versions can be 3D printed simultaneously.

Although freshly 3D printed car parts will generally require some post-processing steps like cleaning, cutting or curing, the faster build times usually make up for this additional time.

Lightweight car parts

With 3D printing, the entire part is built up (or down) from one side to the other. With control of every single part in between, the internal material can be placed in any desired amount or arrangement. Resulting in lightweight 3D printed car parts that can go from completely hollow, up to solid, and any density in between.

Especially unique to 3D printing, are internal lattice structures which can be added to hollow parts. These can aid 3D printed cars in physical requirements like strength, flexibility or temperature dissipation.

Also unique to 3D printing, is a design process called Topology Optimization. Where it is possible to create organically shaped car parts that contain material only along lines of stress, and leave out the rest of the part's original volume. These more natural looking parts have almost identical performance to their traditional predecessors, but greatly reduce the weight of 3D printed cars.

Large range of materials, colours, transparency, hardness & flexibility

3D printed cars can be printed with almost any of these characteristics that a designer may require. The range of 3D printing materials is already vast and growing rapidly. Millions of colours are available in high definition and their placement is digitally controlled. Completely transparent resins are common. Even glass is now available. And the hardness and flexibility can be adjusted to any level required.

Non-uniform car parts

By adding each individual part of each individual layer, 3D printing allows car designers to control precisely what material and characteristic they require for each area of the 3D printed car part. They can build multi-material parts with varying levels of resolution, density, colour, transparency, hardness and flexibility, all within the same part.

Unprecedented shape complexity, resolution, textures and thin features

With most traditional manufacturing methods, physical cutting tools are used to create these characteristics. But with 3D printing, the tools used are light waves and nozzles. Both of which, can be emitted or made at far smaller sizes than the traditional tools. Even down to the nanoscale.

This allows for 3D printed cars with shapes and features that are much finer and more intricate than before.

Whether they were generated algorithmically, digitally sculpted, parametrically modelled or 3D scanned, many designs that car makers were unable to manufacture previously, are now possible.

Parts with internal cooling channels

With the ability to print hollow parts and cavities, 3D printers are able to build 3D printed car parts with internal cooling channels through which liquids can be circulated to cool the part down. Cavities and channels can be created and routed anywhere within the part that is required. Sections of complex shapes that were previously difficult to cool, are now possible to reach with intricate cooling channel networks.

Design cars with freedom from traditional constraints

Before 3D printing, each traditional method of manufacture had its own constraints that hindered the design process and reduced the availability of shapes. Whether it was a cutter or a mold, each tool restricted the creation of shapes in some way.

But with 3D printing, because we can accurately place and bond the newly added building material in any location we desire, it is now possible to create almost any 3D printed car part that can be imagined.

Low-volume production

3D printed car parts are produced directly from their source material on demand. There is no need for expensive molds, tooling or any other manufacturing process to be completed before printing can begin. Making it a more cost-effective and efficient solution for low-volume production runs or for rare and legacy car parts.

Combined manufacturing processes

The relatively diverse capabilities of 3D printers allows for car parts that previously required multiple manufacturing processes, to be accomplished all in a single 3D print. Consider some example cases:

Parts that required painting after manufacture, can now just be printed in colour.

A hard part that required softer sections to be attached after its manufacture, can now just be printed with all the hard and softer parts in a single print.

A molded shape that required additional holes or trimming after being cast, can now just be printed with all the required features.

Or making a part with a highly detailed section, that requires a separate and more accurate machine to add it afterwards.

3D printed car parts can all now be printed on a single machine, and in a single print. Which saves the manufacturer time and the cost of requiring multiple machines.

Supply chain efficiency and less car parts in stock

Because of a 3D printer’s ability to combine multiple manufacturing processes and 3D print car parts rapidly, the branches of a global automaker might only require 3D printers on site. Instead of maintaining large inventories of parts that may never be used, design files for any car part can just be downloaded and 3D printed with fast enough turn-arounds, lower costs and less waste.

Reduced waste

Traditional manufacturing methods like machining, require that a block of material be trimmed away, leaving the desired shape behind (Subtractive Manufacturing). This means that the material that was removed, is wasted. With 3D printing, the material used to construct the part is usually the only material used in the manufacturing of the part (Additive Manufacturing). Except for 3D printing methods where disposable support structures are required.

For other traditional methods like molding, casting, extruding & vacuum forming, molds need to be created and usually replaced. Unlike 3D printing where no molds are required.

An additional benefit with 3D printed car parts, is the ability to rapidly print prototypes to test new designs with. This allows car designers to identify design flaws before creating entire molds that could be wasted if a design change needs to be made. Which is often the case.

Below are some of the best 3D Printed Cars from around the world.

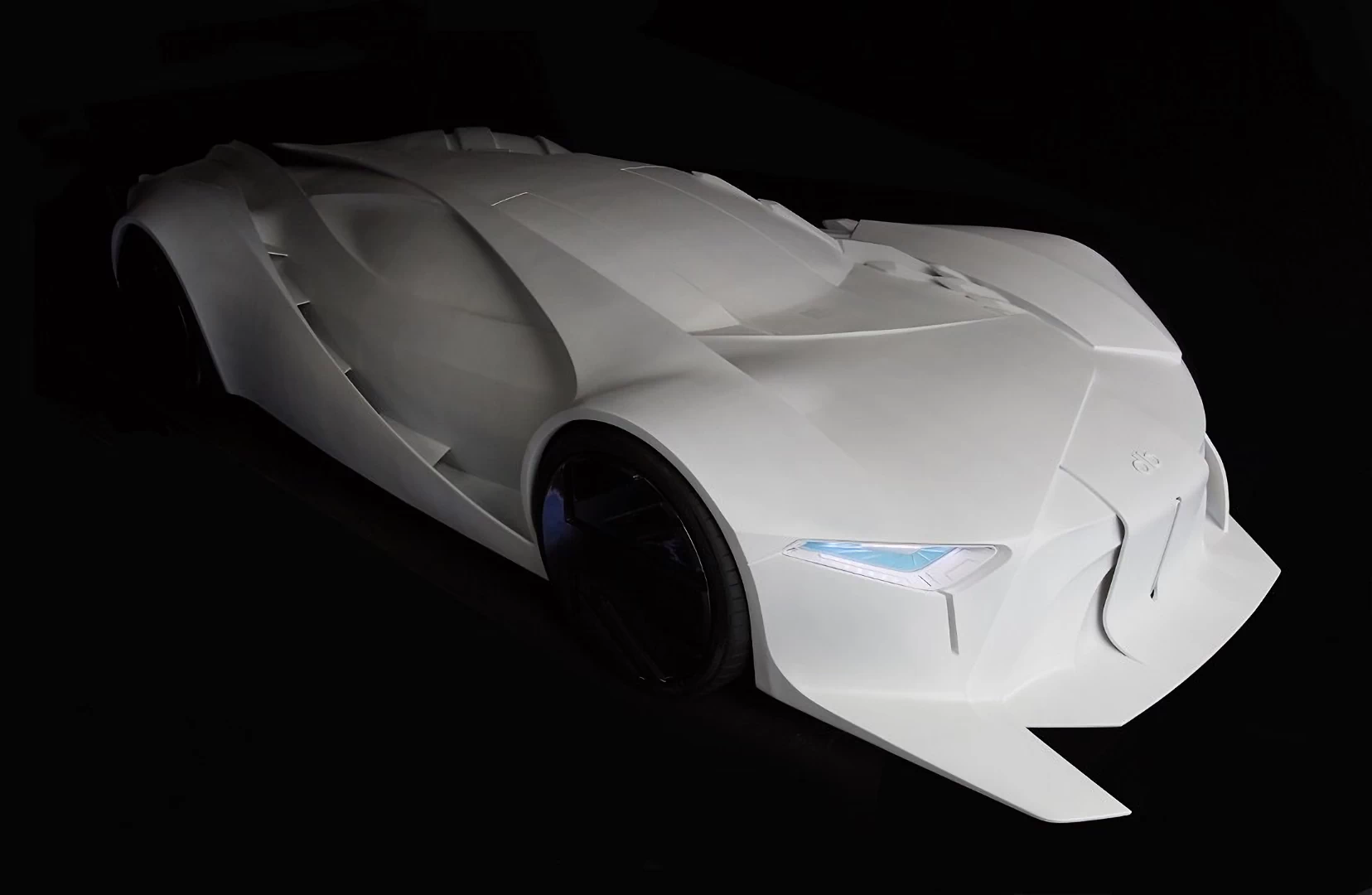

Light Cocoon Concept by EDAG

EDAG designers used a leaf as inspiration in their search for the ultimate, lightweight outer car skin. Like a leaf, this concept car has a tough textile outer skin stretched over the lightweight 3D Printed exoskeleton.

3D Printed with SLA Resin in Germany

Lamborghini Aventador by Sterling Backus

After driving a Lamborghini Aventador on his Forza Xbox car video game, Xander asked his dad if they could build one. Lucky for him, his dad Sterling was the kind of dad that was up for the challenge. Fast forward 4 years later, and they have 3D Printed a drivable Lamborghini Aventador that is almost an exact replica of the original car.

3D Printed with Plastic FDM in USA

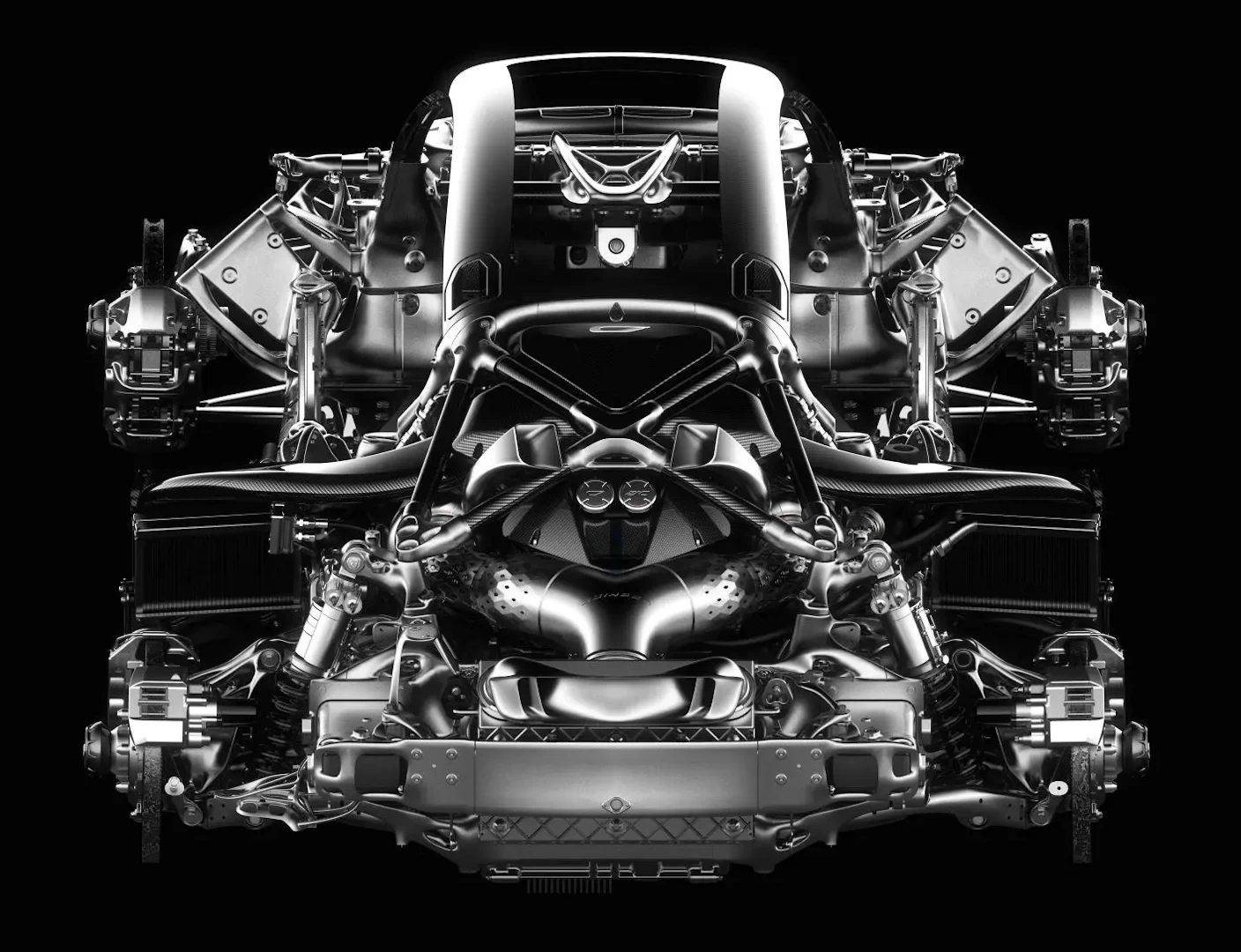

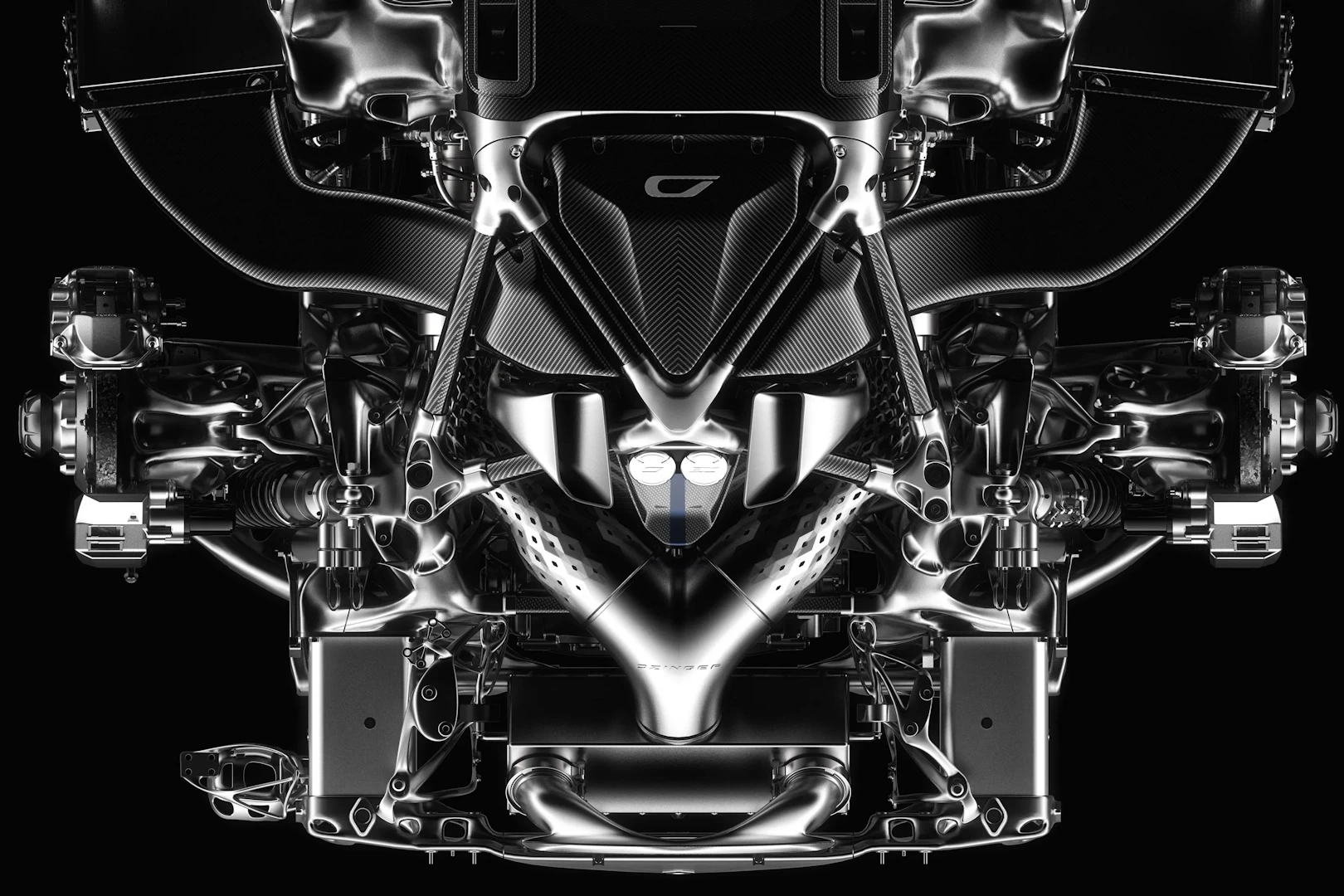

Czinger 21C by Divergent

Divergent has revolutionized the automotive industry by 3D printing the car's metal chassis itself. Using SLM's large NXG XII 600 printers, has allowed them to use topology optimization all of their parts, and reduce the overall weight of the car as has never been possible before.

3D Printed with Metal SLM in USA

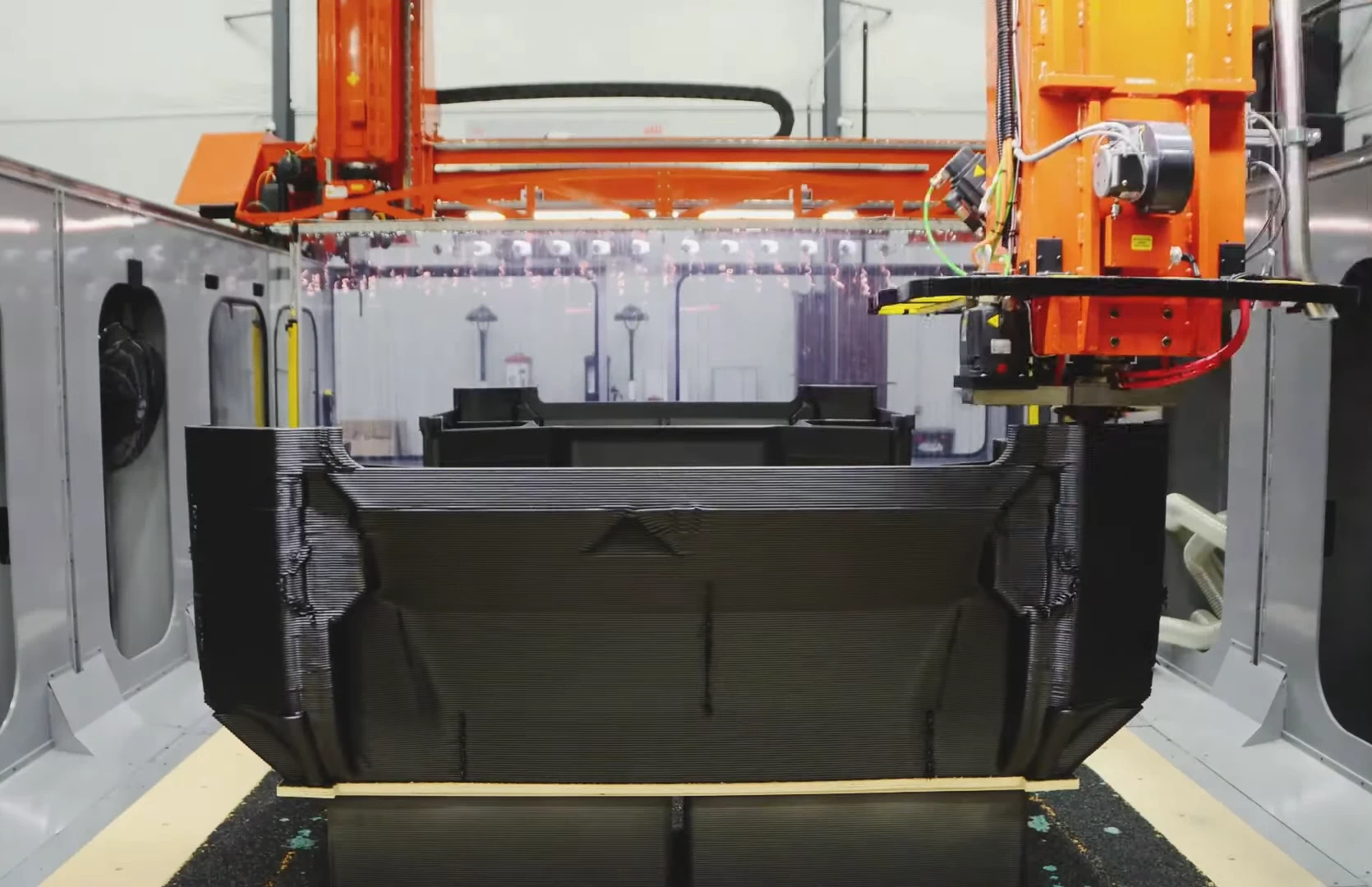

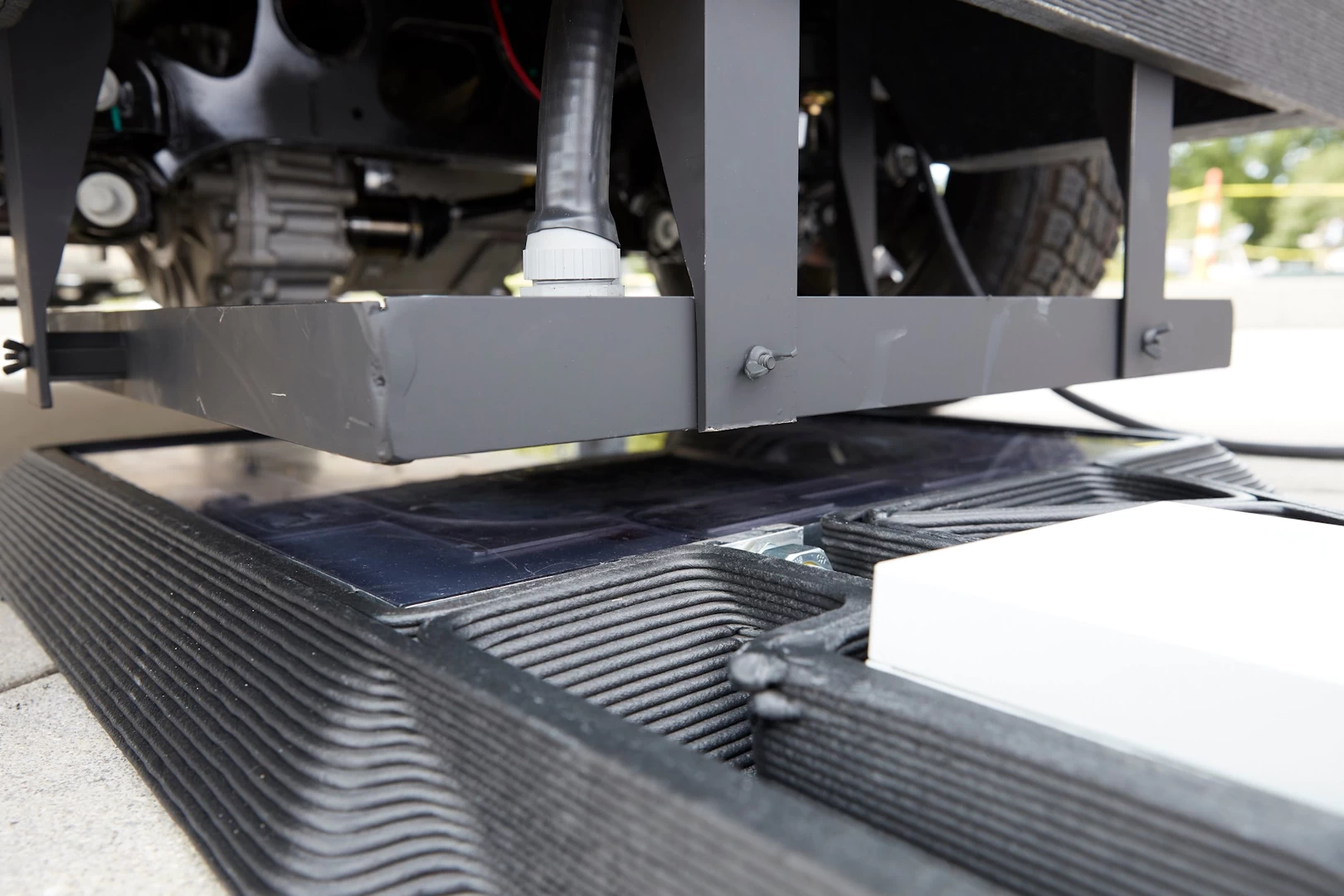

Cobra by Oak Ridge National Laboratory

To celebrate the iconic Cobra’s 50th anniversary, Carroll Shelby International Inc. and US Department of Energy’s Oak Ridge National Laboratory (ORNL) joined together to 3D Print this Electric Cobra car for the Detroit Auto Show. Using their Big Area Additive Manufacturing (BAAM) machine, it took the team 24hrs to print the 225kg of printed car parts including the body.

3D Printed with Plastic FDM in USA

1952 Willy's Army Jeep by Oak Ridge National Laboratory

The US Department of Energy’s Oak Ridge National Laboratory (ORNL) decided to demonstrate new automotive manufacturing technologies by 3D Printing an electric replica of a 1952 Willy's Army Jeep using their Big Area Additive Manufacturing (BAAM) machine.

3D Printed with Plastic FDM in USA

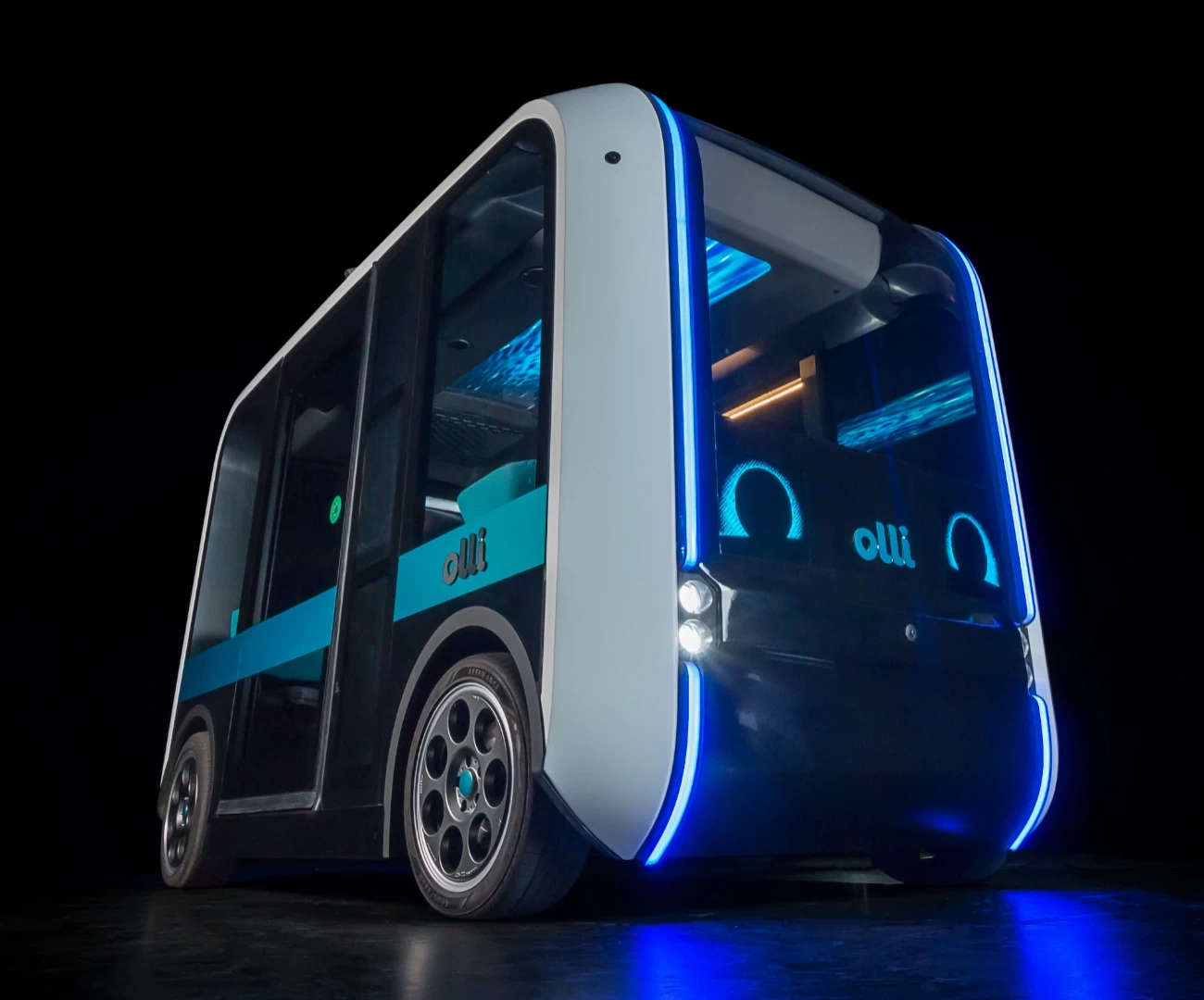

Olli by Local Motors

Olli is an autonomous electric shuttle designed to transport 12 passengers in low speed environments. Using Big Area Additive Manufacturing (BAAM) process, up to 80% of it including the printed body, can be printed and assembled in 10hrs.

3D Printed with Plastic FDM in USA

A portrait of db by Takumi Yamamoto

Takumi Yamamoto's passion for automotive design and fascination with David Bowie finally came together when he decided to mix the two. Using a car as his own artistic medium, Takumi sculpted it in the spirit of David Bowie. And Marie 3D used a Massivit 1800 3D Printer to bring this car to life.

3D Printed with Resin FDM in France

Yoyo by XEV

The Yoyo is a compact electric 2-seater car with an interior and exterior that is 3D printed on a BigRep PRO printer.

3D Printed with Plastic FDM in Italy

LM3D Swim by Local Motors

The LM3D Swim served as a prototype car for future design from Local Motors, that are capable of exceeding Federal Motor Vehicle Safety Standards. The design was selected from design competition they ran and took 2 months to complete. It is 75% 3D printed including the car's chassis and body.

3D Printed with Plastic FDM in USA

AMIE Utility Vehicle by Oak Ridge National Laboratory

This natural-gas-powered hybrid electric vehicle was used to demonstrate Additive Manufacturing Integrated Energy (AMIE) demonstration by the Department of Energy’s Oak Ridge National Laboratory (ORNL). The team connected the vehicle with a solar-powered building to create an integrated energy system, where they can both power each other.

3D Printed with Plastic FDM in USA

Hato sablé by Honda & Kabuku Inc

This is a short range electric Micro Commuter created for the Japanese confectionary maker Toshimaya, to carry out deliveries of its famous ‘Hato sablé’ ‘(Dove shaped Shortbread). The 3D printed exterior panels clad the chassis, which is constructed from a rigid and lightweight pipe frame structure.

3D Printed with Plastic FDM in Japan

Share on

Other Blog Lists